Rubber Lining (Services)

-

Payment

T/T

-

MOQ

1 meter (m)

-

Supply Ability

9,999,999 meter (m) per One-Time

-

Supply Details

Customization

MOQ: Depends on item and quantity

-

Country of sale

Americas, Asia, Middle East, Europe, World Wide

-

PRICE

-

FOB

Depend on quantity

-

DAP

Depend on quantity

-

CIF

Depend on quantity

-

ITEM SPECIFICS

-

Brand

Model MJ TSR Rubber LiningMJ TSR

-

origin

Republic of Korea

-

Size(Capacity)

Pipe Diameter: DN 80 to DN 2600 / Vessel Size: Up to Ø3,000mm × 8,000mm (L)

-

Function

Corrosion and abrasion resistance, Chemical protection, Internal anti-wear barrier for steel equipme

-

Material

Natural Rubber (Soft, Hard), Neoprene, Butyl, EPDM, Ebonite

-

Color

Black (standard) – others upon request

-

Dimensions

Customized per application (surface coverage basis)

-

Weight

Varies by size, thickness, and structure – typically 5–10 kg/m²

-

Style

Bonded rubber lining – sheet, precured, or molded application

-

Condition

New, On-site or factory-installed

-

Features

ISO-standard surface preparation, Spark tested, Durable in aggressive chemical environments

PRODUCT DESCRIPTION

Rubber Lining (Services)

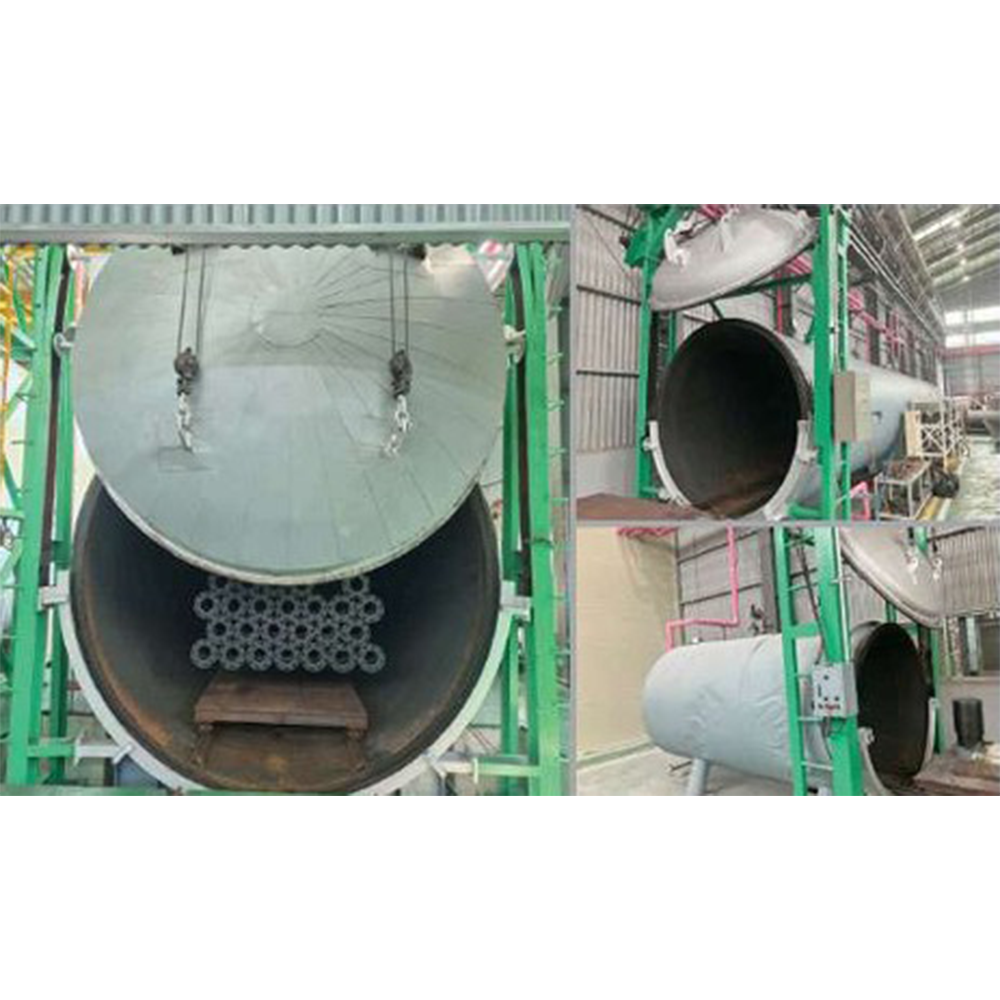

MJ TSR’s Rubber Lining is a premium industrial corrosion-resistant solution, designed to extend the life of pipelines, tanks, vessels, and structures in the harshest operational environments. Backed by decades of experience and cutting-edge in-house manufacturing, MJ TSR provides lining services using specially formulated rubber compounds to resist chemical attack, abrasion, erosion, and thermal stress.

Our rubber lining systems are tailored for sectors such as power plants (BOP), industrial pipelines, chemical plants, offshore plants, and marine & wind power facilities. Using a variety of rubber types — including soft natural rubber, hard rubber (vulcanized), and specialty synthetic elastomers — we optimize chemical compatibility, mechanical protection, and application durability.

All lining work is performed under strict surface preparation standards (e.g., SSPC-SP10, ISO 8501-1 Sa 2.5), followed by precise rubber application and cure processes. We handle a wide range of product shapes including elbows, reducers, branches, tanks, valves, and flanges, ensuring secure bonding and uniform rubber thickness.

Our testing process includes spark testing, thickness checks, hardness measurement, and visual inspection using advanced tools, ensuring flawless surface protection. MJ TSR’s turnkey approach allows clients to achieve reliable anti-corrosion performance and reduce long-term maintenance costs in aggressive process environments.

Our rubber lining systems are tailored for sectors such as power plants (BOP), industrial pipelines, chemical plants, offshore plants, and marine & wind power facilities. Using a variety of rubber types — including soft natural rubber, hard rubber (vulcanized), and specialty synthetic elastomers — we optimize chemical compatibility, mechanical protection, and application durability.

All lining work is performed under strict surface preparation standards (e.g., SSPC-SP10, ISO 8501-1 Sa 2.5), followed by precise rubber application and cure processes. We handle a wide range of product shapes including elbows, reducers, branches, tanks, valves, and flanges, ensuring secure bonding and uniform rubber thickness.

Our testing process includes spark testing, thickness checks, hardness measurement, and visual inspection using advanced tools, ensuring flawless surface protection. MJ TSR’s turnkey approach allows clients to achieve reliable anti-corrosion performance and reduce long-term maintenance costs in aggressive process environments.

Key Features

Custom rubber lining for corrosion, abrasion, and chemical resistance

Supports wide range of shapes and sizes (up to Ø3,000mm × 8,000L)

Compatible with acids, alkalis, slurry, wastewater, and industrial chemicals

In-house production and formulation of rubber sheets and adhesives

Applied with strict surface blasting, bonding, and curing controls

Used in power generation, mining, chemical processing, and offshore plants

Supports wide range of shapes and sizes (up to Ø3,000mm × 8,000L)

Compatible with acids, alkalis, slurry, wastewater, and industrial chemicals

In-house production and formulation of rubber sheets and adhesives

Applied with strict surface blasting, bonding, and curing controls

Used in power generation, mining, chemical processing, and offshore plants

Recommended Use

Suitable for highly corrosive or erosive services in chemical, mining, or marine environments

Consult MJ TSR’s engineering team for best-fit lining material and installation instructions

Consult MJ TSR’s engineering team for best-fit lining material and installation instructions

Specifications (Typical)

| Rubber types | Soft NR, Hard Rubber, Neoprene, Butyl, EPDM, Ebonite |

| Thickness | Typically 3–10mm (customizable) |

| Shapes | Elbow, Reducer, Branch, Tank, Pipe, Valve |

| Pipe Sizes | DN 80 to DN 2,600 |

| Surface prep | Sa 2.5 (SSPC-SP10) |

| Testing | Spark test, Hardness test, Thickness test |

| Function | Corrosion and abrasion resistance, Chemical protection, Internal anti-wear barrier for steel equipment |

| Features | ISO-standard surface preparation, Spark tested, Durable in aggressive chemical environments, Long service life |

| Origin | Republic of Korea |

About Us

∙ Company Overview

MJ TSR Co., Ltd. is a trusted manufacturer of rubber products, established in 1973 in Busan, Korea. With decades of expertise, we supply high-quality rubber sheets, conveyor belts, and PE-lined pipes for industries worldwide, including shipbuilding, petrochemicals, and power plants. We are committed to delivering reliable solutions and long-term value to our global clients.

Factory Information

MJ TSR operates production facilities in our main branch in Busan, Korea. We also have branches in Ulsan, Korea, and Qingdao, China. We produce conveyor belts, rubber sheets, and molded products. We also have rubber lining, PE lining, and welding services. Our plants are equipped with advanced manufacturing lines and follow strict quality control for timely and consistent output.

MJ TSR Co., Ltd. is a trusted manufacturer of rubber products, established in 1973 in Busan, Korea. With decades of expertise, we supply high-quality rubber sheets, conveyor belts, and PE-lined pipes for industries worldwide, including shipbuilding, petrochemicals, and power plants. We are committed to delivering reliable solutions and long-term value to our global clients.

Factory Information

MJ TSR operates production facilities in our main branch in Busan, Korea. We also have branches in Ulsan, Korea, and Qingdao, China. We produce conveyor belts, rubber sheets, and molded products. We also have rubber lining, PE lining, and welding services. Our plants are equipped with advanced manufacturing lines and follow strict quality control for timely and consistent output.

∙ Our Service

We offer customized production of rubber sheets, conveyor belts, rubber lining, PE lining, and induction bends.

Our service includes design support, technical consultation, prompt global delivery, and reliable after-sales care. With a client-first mindset, we ensure every product meets the functional and environmental needs of your industry.

We offer customized production of rubber sheets, conveyor belts, rubber lining, PE lining, and induction bends.

Our service includes design support, technical consultation, prompt global delivery, and reliable after-sales care. With a client-first mindset, we ensure every product meets the functional and environmental needs of your industry.

∙ Our Policy

MJ TSR is driven to earn customer satisfaction, to secure competitiveness in the world market, to be professional in the business fields and to manage the organization according to systems.

We follow ISO 9001, ISO 45001, and OHSAS 18001 standards, prioritize eco-conscious operations, and ensure safe working environments. We value transparency and integrity in all business practices, aiming to build lasting partnerships based on trust and performance.

MJ TSR is driven to earn customer satisfaction, to secure competitiveness in the world market, to be professional in the business fields and to manage the organization according to systems.

We follow ISO 9001, ISO 45001, and OHSAS 18001 standards, prioritize eco-conscious operations, and ensure safe working environments. We value transparency and integrity in all business practices, aiming to build lasting partnerships based on trust and performance.

R&D CERTIFICATE

-

- EVPU Certificate IEC 61111

- EVPU

- 2025.01.29

- 인증서보기

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Telegraphic Transfer : T/T

- Name : JO SEOL LIN

SHIPPING

Shipping from :

Republic of Korea

- 17 Hwajeonsandan 2-ro, Gangseo-gu, Busan (46739)

MJ TSR Co., Ltd.

The person in charge

SEE YOUNG JOAddress

17 Hwajeonsandan 2-ro, Gangseo-gu, Busan (46739)

Introduction

Company Overview

MJ TSR Co., Ltd. is a trusted manufacturer of rubber products, established in 1973 in Busan, Korea. With decades of expertise, we supply high-quality rubber sheets, conveyor belts, and PE-lined pipes for industries worldwide, including shipbuilding, petrochemicals, and power plants. We are committed to delivering reliable solutions and long-term value to our global clients.

Factory Information

MJ TSR operates production facilities in our main branch in Busan, Korea. We also have branches in Ulsan, Korea, and Qingdao, China. We produce conveyor belts, rubber sheets, and molded products. We also have rubber lining, PE lining, and welding services. Our plants are equipped with advanced manufacturing lines and follow strict quality control for timely and consistent output.

Our Service

We offer customized production of rubber sheets, conveyor belts, rubber lining, PE lining, and induction bends.

Our service includes design support, technical consultation, prompt global delivery, and reliable after-sales care. With a client-first mindset, we ensure every product meets the functional and environmental needs of your industry.

Our Policy

MJ TSR is driven to earn customer satisfaction, to secure competitiveness in the world market, to be professional in the business fields and to manage the organization according to systems.

We follow ISO 9001, ISO 45001, and OHSAS 18001 standards, prioritize eco-conscious operations, and ensure safe working environments. We value transparency and integrity in all business practices, aiming to build lasting partnerships based on trust and performance.

-

- Business Type :

- Manufacturer

-

- Main Product :

- Rubber Sheet/Conveyor Belt/Lining

-

- Established :

- 1973-04-28

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 101~500 people

R&D CERTIFICATE

-

- EVPU Certificate IEC 61111

- EVPU

- 2025.01.29

- 인증서보기

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 101~500 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

PLATINUM

PLATINUM

- MJ TSR Co., Ltd. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★