ITEM SPECIFICS

-

Brand

Wedge

-

origin

Republic of Korea

-

Size(Capacity)

TBD

-

Color

Silver

-

Function

Securing and insulating the stator windings

-

Material

B50A886A

PRODUCT DESCRIPTION

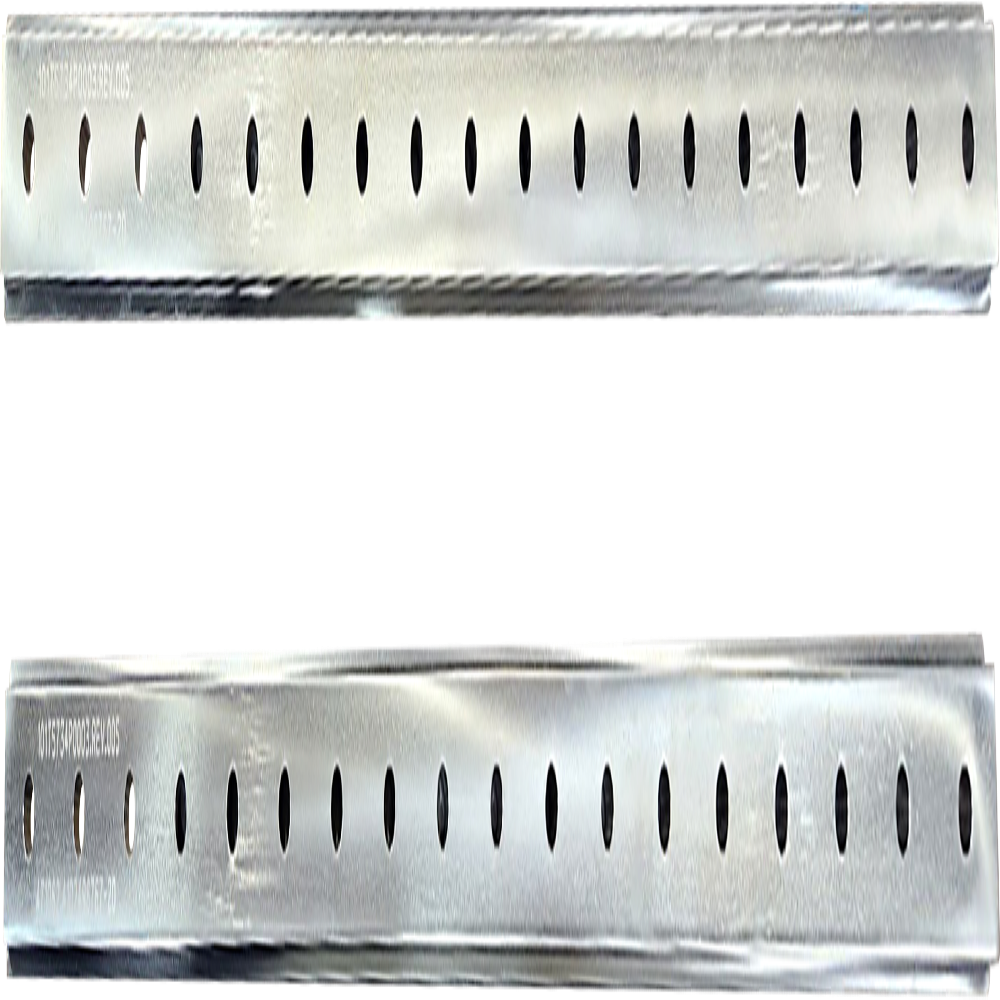

A generator wedge is a component used in generators, specifically within the stator, to secure and insulate the stator windings. These wedges are crucial for maintaining the integrity and performance of the generator, as loose wedges can lead to vibration, insulation wear, and potential electrical faults.

Generator wedges are designed to fit into the slots of the stator core, pressing against the stator windings and holding them firmly in place. This prevents the windings from vibrating and rubbing against the stator core, which can cause damage to the insulation.

Maintaining proper wedge tightness is essential for reliable generator operation. Loose wedges can result in:

Increased vibration: Vibration can damage the insulation and lead to eventual failure.

Insulation wear: Rubbing of the windings against the stator core can wear away the insulation, potentially causing short circuits.

Reduced generator efficiency: Vibration and insulation damage can negatively impact the generator's performance.

Increased vibration: Vibration can damage the insulation and lead to eventual failure.

Insulation wear: Rubbing of the windings against the stator core can wear away the insulation, potentially causing short circuits.

Reduced generator efficiency: Vibration and insulation damage can negatively impact the generator's performance.

Wedges can be made from various materials, including those with magnetic properties. The specific material and design are chosen to optimize electromagnetic performance and cooling.

R&D CERTIFICATE

PAYMENTS DETAILS

This supplier supports payments for offline orders

- OT

- Name : Hyeong Mo Ahn

SHIPPING

Shipping from :

Republic of Korea

- 139 Hongti-ro, Saha-gu, Busan (49489)

DYM CO., LTD.

The person in charge

Sung-Jin AhnAddress

139 Hongti-ro, Saha-gu, Busan (49489)

Introduction

We, DYM, have been supplying bearings to various industry field such as Gas turbine, Steam turbine, Generator, Nuclear power plant and Marine engine for last 40 years .

We have high-level machining and quality capabilities through business experience with global leading companies. Our representative main customers are GE, Mitsubishi, TOSHIBA, MAN E&S and WARTSILA.

We, DYM, do our best to meet customer’s needs and requirements through continous investment in R&D, modernization of facilities and customized bearing solution.

-

- Business Type :

- Other

-

- Main Product :

-

- Established :

- 2004-11-19

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 51~100 people

R&D CERTIFICATE

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- 51~100 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

GOLD

GOLD

- DYM CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★